System integration has become one of the main challenges for companies working with third-party logistics providers. WMS, TMS, ERP, CMS, and marketplaces often operate in silos and struggle to communicate with one another. As a result, operational teams spend more time manually managing data flows. Phone calls, emails, and data checks represent hours lost that could otherwise be dedicated to improving logistics performance.

Spacefill positions itself as a modern IT system designed to solve this problem at scale. Rather than acting as a simple technical connector, Spacefill operates as a SaaS middleware an integration layer that connects logistics systems, partners, and data sources to deliver a unified and seamless operational experience.

This article explains what a 3PL integration platform is, why traditional approaches are reaching their limits, and how Spacefill stands out as one of the most advanced logistics connectors on the market.

What Is a 3PL Integration Platform?

A 3PL integration platform connects a company’s internal systems with its external logistics partners.

Its primary role is to ensure reliable and seamless data flows between:

- ERPs

- Warehouse Management Systems (WMS)

- Order Management Systems (OMS)

- Transportation Management Systems (TMS)

- CMS and marketplaces

Without a proper integration layer, companies rely on fragmented processes: Excel files, emails, PDFs, or fragile EDI connections. This leads to delays, errors, and limited visibility across the supply chain.

A modern 3PL integration platform goes beyond basic connectivity by adding visibility, orchestration, automation, and operational intelligence.

Why Is Integration a Major Challenge in Modern Logistics?

Most logistics organizations operate within fragmented ecosystems.

The most common challenges include:

1. Common Challenges for Shippers

- multiple 3PLs using different WMS

- limited visibility into outsourced inventory

2. Common Challenges for 3PLs

- manual order entry from emails or Excel files

- a strong dependency on IT teams for even minor changes

3. Challenges Shared by Shippers and 3PLs

- heterogeneous data formats across systems

- slow onboarding of new logistics partners

Traditional integrations are often built as custom point-to-point connections. While they may work in the short term, they quickly become complex and very expensive to maintain as the logistics network grows.

Each new warehouse, client, or carrier increases overall complexity exponentially.

What Makes a Good 3PL Connector?

A high-performing 3PL integration platform must address both technical and operational requirements.

Essential Technical Capabilities

- API and EDI compatibility developing APIs and EDIs in-house is time-consuming and costly; by pooling integration projects, an integration platform can mutualize development costs and offer competitive pricing

- ability to connect to multiple ERP and WMS systems

- scalable architecture to support growth

- native connectors to a wide range of systems

- secure data exchanges

- fast deployment without heavy custom development

Essential Operational Capabilities

- centralized visibility across all partners

- automation of repetitive logistics tasks

- standardized processes across warehouses

- incident and exception management

- clear logistics performance tracking with precise KPIs and dashboards

- connector monitoring and control to resolve issues without relying on IT teams

Most traditional connectors focus almost exclusively on the technical layer. Spacefill was designed to address both dimensions simultaneously.

Why Does Spacefill Act as a Logistics Integration Layer Rather Than a Simple Connector?

Spacefill is not just a bridge between shippers’ and 3PLs’ systems. It is a collaborative platform built specifically for logistics operations involving external partners.

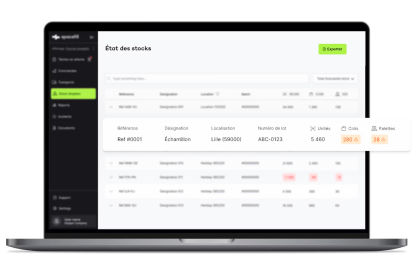

Instead of multiplying individual integrations, Spacefill operates as a centralized connectivity hub that links all logistics stakeholders through a single interface. A shipper managing both in-house warehouses and multiple third-party logistics providers can access all internal and external logistics data within one platform. This enables a consolidated view of inventory and orders, both globally and warehouse by warehouse.

This approach makes it possible to:

- connect multiple 3PLs without multiplying integration flows

- standardize logistics processes across different warehouses

- centralize data from heterogeneous systems

- significantly reduce reliance on manual processes

Spacefill sits between internal systems and external partners, orchestrating data, workflows, and real-time communication.

What Types of Integrations Does Spacefill Support?

Spacefill covers all integration needs of a modern 3PL ecosystem.

ERP Integrations

Spacefill connects to ERPs to synchronize:

- orders

- inventory levels

- deliveries

- billing data into a centralized document hub

This ensures ERP data consistency, even when logistics execution is outsourced to multiple partners.

WMS Integrations

Spacefill interfaces with various WMS solutions used by logistics providers.

Key benefits include:

- real-time visibility across multi-warehouse inventory

- standardized order flows regardless of the WMS in use

- accelerated onboarding of new logistics partners

Order and Document Automation

One of Spacefill’s key differentiators is order processing automation.

Using AI, Spacefill can automatically extract order data from:

- emails

- PDF documents

- Excel files

This eliminates manual data entry and drastically reduces human error.

Transportation and Dock Coordination

Spacefill also integrates transportation and dock management within the same platform, making coordination between warehouses, carriers, and shippers easier.

How Does Spacefill Compare to Traditional 3PL Connectors?

| Capability | Traditional Connectors | Spacefill |

|---|---|---|

| Integration model | EDI | Centralized hub |

| Multi-WMS support | Limited | Native |

| Order automation | Manual or external | Built-in AI |

| Partner onboarding | Slow | Fast and standardized |

| Operational visibility | Fragmented | Centralized |

| Incident management | External tools | Integrated |

| Scalability | Low to medium | High |

This difference in approach explains why Spacefill is better suited to complex logistics environments.

Why Is Spacefill Built to Scale?

Modern supply chains constantly evolve. New warehouses, clients, and sales channels must be integrated quickly without disrupting existing operations.

Spacefill was designed with this reality in mind.

Its key scalability strengths include:

- reusable connectors

- standardized logistics workflows

- minimal IT effort for new deployments

- ability to handle large volumes of orders and partners

- centralized control without operational bottlenecks

Companies using Spacefill can grow their logistics networks without rebuilding their integration architecture at every step.

Who Gets the Most Value from Spacefill Integrations?

3PL Providers

- faster client onboarding

- reduced operational complexity

- improved visibility for clients

- higher service quality

- strong competitive advantage in RFPs

Brands and Shippers

- full control over outsourced logistics

- real-time inventory visibility

- fewer errors and disputes

- simplified communication with multiple 3PLs

- real-time synchronization across sales channels

Logistics and Supply Chain Teams

- reduced manual work

- fewer errors

- fewer emails and customer calls

- higher data quality

- faster issue resolution

- more time focused on performance improvement

Key Takeaways

- a 3PL integration platform is now essential in modern logistics

- traditional connectors quickly reach their limits in complex ecosystems

- Spacefill acts as a logistics integration layer, not just a technical bridge

- the platform combines system connectivity with operational intelligence

- its centralized, AI-driven approach makes it one of the most advanced 3PL connectors on the market

FAQ

Spacefill operates as a centralized integration platform: it connects multiple systems and partners through a single hub, automates workflows using AI, and provides full real-time operational visibility.